CAPTure

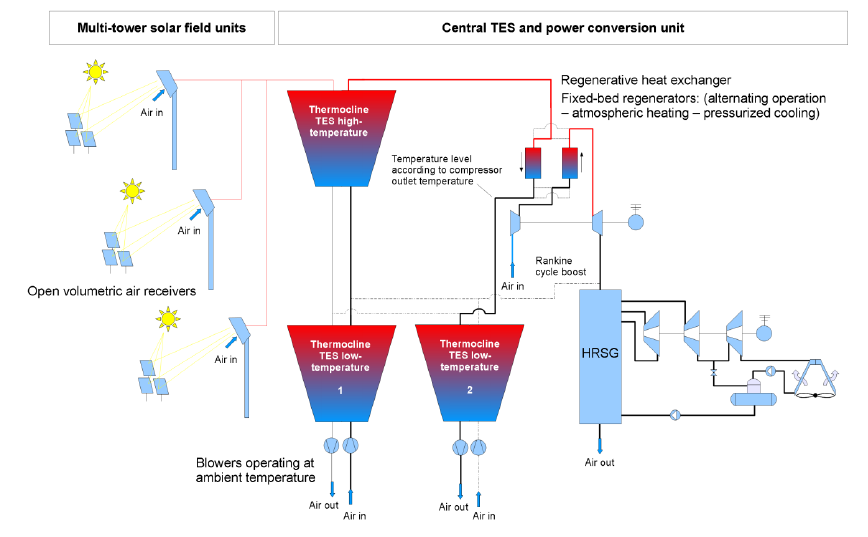

The CAPTure H2020 research project investigated the performance of an innovative solar powered combined cycle plant. The CAPTure power plant concept is shown in the Figure. The innovation is that an open volumetric air receiver drives a combined cycle plant. The atmospheric air circuit is coupled with the pressurized air circuit of the topping Brayton cycle via a regenerative heat exchange system working in alternating modes (atmospheric heating, pressurized cooling). In order to provide dispatchability, a high-temperature thermocline thermal energy storage (TES) system is placed between the solar receiver and the gas turbine.

Unfortunately, the main conclusion of the project is that the combined cycle is not economically competitive when benchmarked against a much simpler Rankine single-cycle power plant layout, applying the same receiver and TES technology. The combined cycle (CC) configuration has a higher LCOE despite its higher solar-to-electric conversion efficiency. The gain in electricity yield is not enough to outweigh the higher investment costs of the more complex CC plant layout. The reasons for the high costs of the CC plant layout are twofold:

- The TES system is complex as it requires low-temperature units for regenerative use of the return-air heat. This is due to the quite small usable temperature difference in the high-temperature thermocline TES, and the fact that HTF (air) recirculation to the receiver is not feasible at high temperatures. Advanced power cycles are typically highly recuperative since the average temperature of heat input to the cycle must be maintained high. This requirement necessarily implies that the HTF temperature interval in which heat is supplied to the cycle is typically small. In the case of the combined cycle, the temperature difference of the HTF is determined by the turbine inlet temperature (TIT) and the compressor exit temperature (CET), which is a function of the Brayton cycle pressure ratio. In the case of reheat, the HTF temperature difference is also determined by the reheat pressure level, i.e. the turbine exit temperature (TET) of the first turbine stage. Ideally, these two temperature levels (CET and TET), should be similar, in order to reduce losses when mixing the two streams (effective HTF return temperature). The effective HTF return temperature is the temperature at which the HTF leaves the power block after all parallel mass flow streams are merged (mixing temperature). At this temperature level, the HTF would then be recirculated to the solar receiver and again heated to the nominal receiver outlet temperature. However, since 100% air recirculation is very difficult to achieve with open volumetric receivers, and the transport of hot air is very inefficient, the CAPTure project considered the use of the return air heat in a regenerative manner, applying two additional units of low-temperature air/rock thermocline TES.

- Very high operating temperatures of the solar receiver (≈1000ºC) limit the receiver’s conversion efficiency and increase costs due to the application of high-temperature materials.

CAPTure Dispatchable Solar Combined Cycle (DSCC)

CAPTure Dispatchable Solar Combined Cycle (DSCC)